Leveraging next-gen sensor stabilization to support IGI in mapping urban heat.

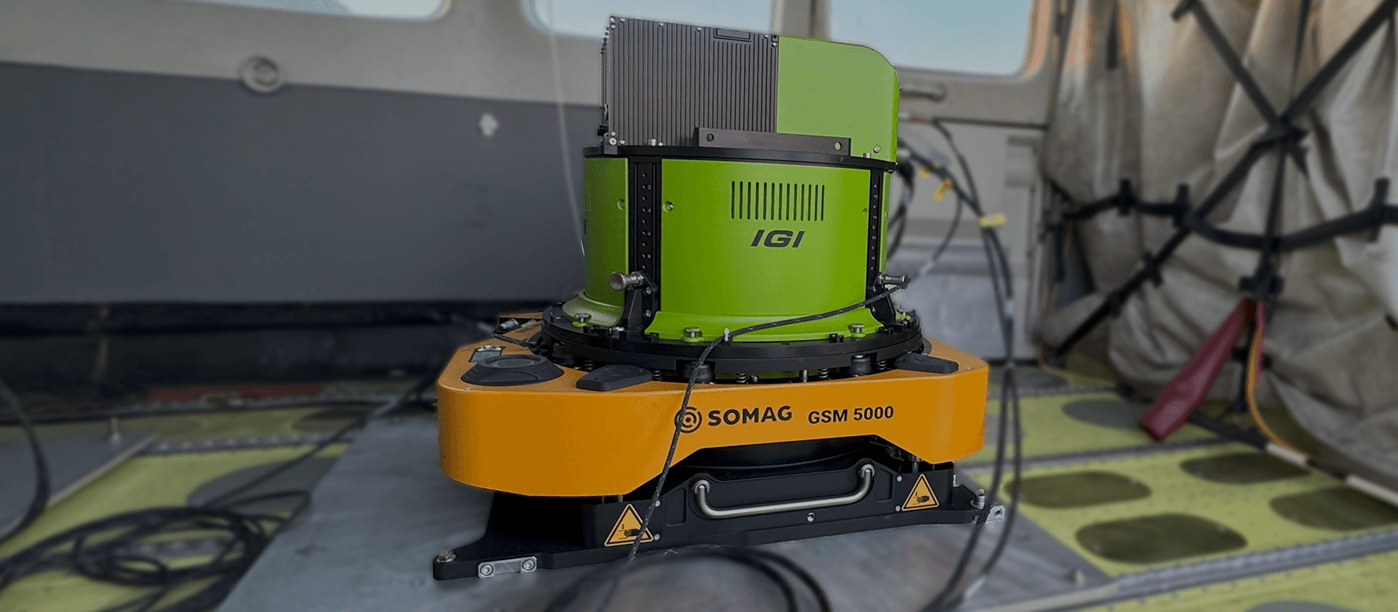

In May 2025, SOMAG AG Jena helped conducting a challenging thermal imaging mission over Phoenix, Arizona, as part of the IGI Lighthouse Project — a collaborative initiative to promote advanced 3D and thermal mapping in the US. The mission relied on our latest gyro stabilization platform, the GSM 5000 stabilizing IGI’s EcoMapper-1280 C thermal sensor. Other companies involved in the project were: ESRI, Fugro, Revolution Flight and InfraTec. Despite difficult flight conditions, the Gyro Mount delivered precise and stable results, showcasing its unique capabilities in real-world, high-stress environments.

Stable Thermal Data – Even in Harsh Flight Conditions

Phoenix is one of the hottest major cities in North America. The Phoenix operation took place under challenging thermal conditions — midday flights in strong updrafts, combined with high external temperatures and unstable air masses. Capturing consistent thermal imagery from the air is demanding – but critical for identifying urban heat hotspots that support climate resilience and urban planning. During the mission, two independent systems were deployed:

- EcoMapper-1280 C on a GSM 5000 Mount (rear hatch)

- UrbanMapper-2P on a GSM 4000 Mount (front hatch)

While both systems performed well, the GSM 5000’s superior stability under turbulence made it the standout solution of the entire mission.

GSM 5000: The Game Changer in Airborne Stabilization

Despite turbulence forcing aircraft speeds to increase beyond 180 knots in some sections, the GSM 5000 delivered rock-stable sensor alignment, ensure consistent data quality. Over 50% more flight time was required due to environmental factors, making stabilization even more critical.

From Zero to Mission-Ready in Hours

The GSM 5000 is built for speed and simplicity. Thanks to its intuitive design and full compatibility with the GSM 4000, operators can install it in less than one hour — with no steep learning curve and no extra training required.

This fast deployment is a real advantage when every hour counts. Whether under tight mission schedules or facing customs and certification hurdles, the GSM 5000 keeps things simple: same base plate, same connection points, and even less weight than its predecessor. That means fewer delays, smoother approvals, and quicker results.

And with a lighter overall weight, larger motion range, and increased internal diameter, the GSM 5000 easily integrates larger and more complex sensors — even in aircraft with limited space.

Design Features that proved their value

Several key design elements of the new GSM 5000 were critical to the mission’s success:

- Minimized risk of mechanical vignetting: The rotation center (pivot point) of the Mount is positioned near the aircraft base level to prevent mechanical vignetting (image shading caused by structural parts) in the sensor’s field of view at larger platform angles

- Quick Deployment: All components worked in “plug & play” fashion, saving valuable field time.

These design choices reflect SOMAG’s ongoing commitment to user feedback — an element acknowledged by the IGI team on-site. “Great that you were listening to customer feedback” commented Kamil Wójcik, Business Development Manager / Technical Sales.

Comparison in all attitude angles

The GSM 5000’s enhanced stabilization capabilities ensured that IGI’s EcoMapper-1280 C could operate at full potential, even under poor conditions. To highlight the stabilization improvements, we have included an interactive diagram comparing the GSM 4000 and GSM 5000 during identical flight conditions.

The data of the stabilization platforms GSM 4000 (previous model) and GSM 5000 (new product generation) were recorded during the test flight and evaluated after the flight. The upper left diagram shows a schematic of the test setup: a light aircraft equipped with a camera payload recording the ground. Any tilt or rotation of the aircraft would immediately lead to blurred or distorted imagery. Therefore, precise stabilization is essential – only with a stable platform can sensors such as cameras, LiDAR scanners, or other measurement systems deliver reliable results.

Combat Plane Movements for sharp data

The three diagrams on the right present the attitude angles Roll, Pitch, and Yaw over a period of 60 seconds. The blue curve (Base) illustrates the unstabilized aircraft motion, which is heavily affected by turbulence. Without stabilization, camera images would constantly be subject to motions and vibrations, making accurate surveying impossible. The white curve, representing GSM 4000, reduces the aircraft motion significantly but repeatedly reaches its limits. This is highlighted by the red markers in the diagrams, which indicate situations where the end-stop boundaries are exceeded. In these moments, the system loses its ability to hold the reference position of 0 deg. In practice, this means that captured images would become blurred or distorted, resulting in data quality degradation or unusable results.

In contrast, the yellow curve, representing GSM 5000 demonstrates much more stable performance. Even under strong turbulence, the new platform remains within its working range and keeps the sensors close to the reference position. Movements are reliably compensated, ensuring that the recorded sensor data remains sharp and consistent.

The significance of these differences becomes clear when looking at the RMS (root mean square) values, which we likte to keep as close as possible to 0.00 degree. In Roll, GSM 4000 achieves an RMS of 0.31 deg, while GSM 5000 reduces this to 0.14 deg. In Pitch, the RMS improves from 0.34 deg to 0.06 deg. In practice, this means that even the smallest motion, which would directly appear in sensor imagery, are considerably minimized.

Pin sharp images without exceeding the endstop

The lower left diagram shows the horizontal plane (Roll vs. Pitch) with the endstop boundaries indicated by dashed lines. These boundaries represent the mechanical working limits of the stabilization platform. It is evident that the GSM 4000 data (white points) exceed these limits multiple times – once the system reaches this state, it can no longer stabilize the aircraft effectively. GSM 5000 (yellow points), however, consistently remains within the boundaries, guaranteeing continuous stabilization throughout the flight. This is of critical importance, since any loss of stabilization directly influences image quality and measurement accuracy.

Results at a Glance: Why GSM 5000 Sets the Standard

In summary, the results clearly demonstrate that the GSM 5000 raises gyro stabilization to a new level. While GSM 4000 reaches its limits under turbulent conditions, GSM 5000 retains full control of the aircraft’s motion.

For airborne survey missions, this means that cameras and other sensors deliver significantly sharper, more consistent, and more precise data, even when flight conditions are challenging. In practice, this translates into higher operational reliability, improved image quality, and more dependable data evaluation within tougher environment.

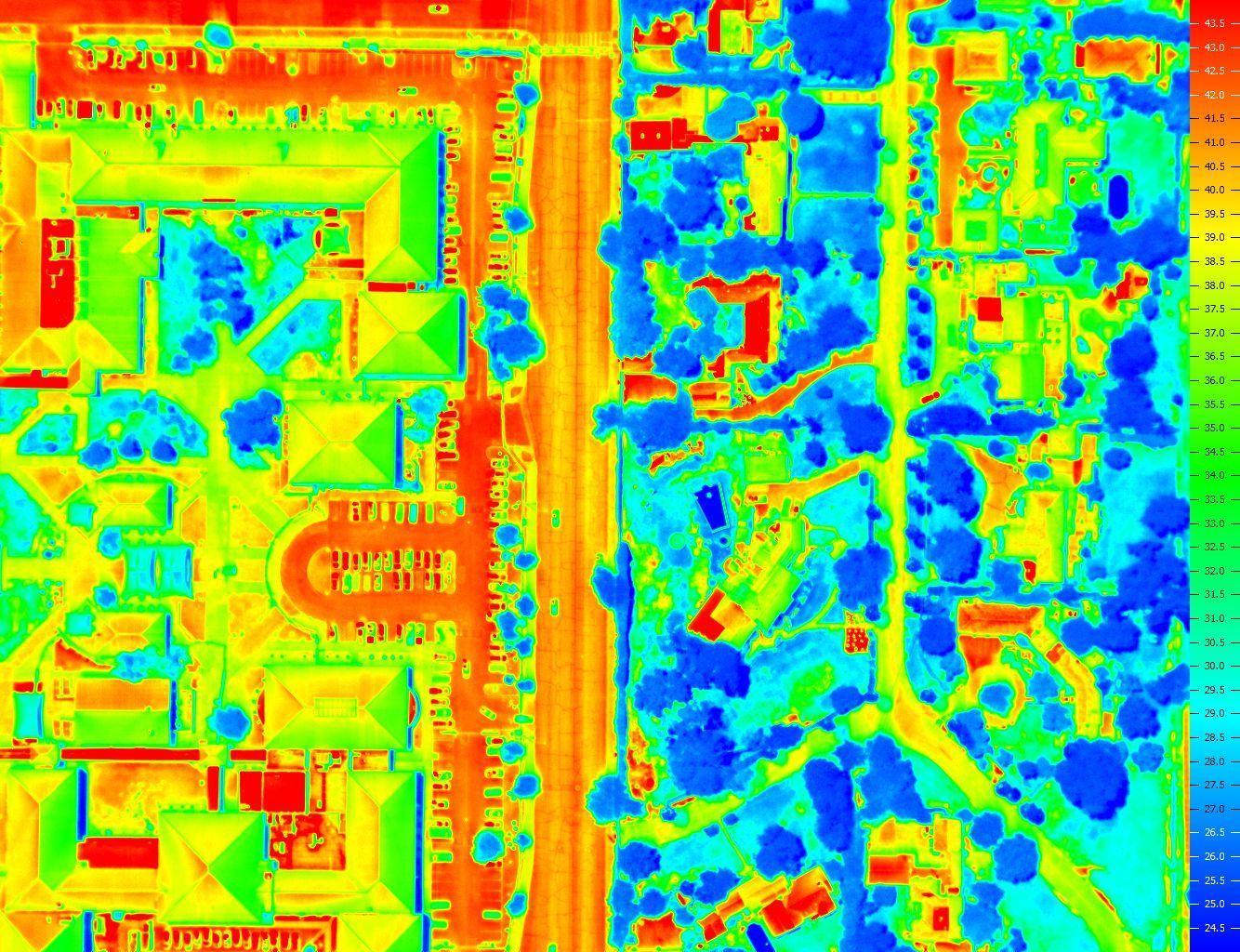

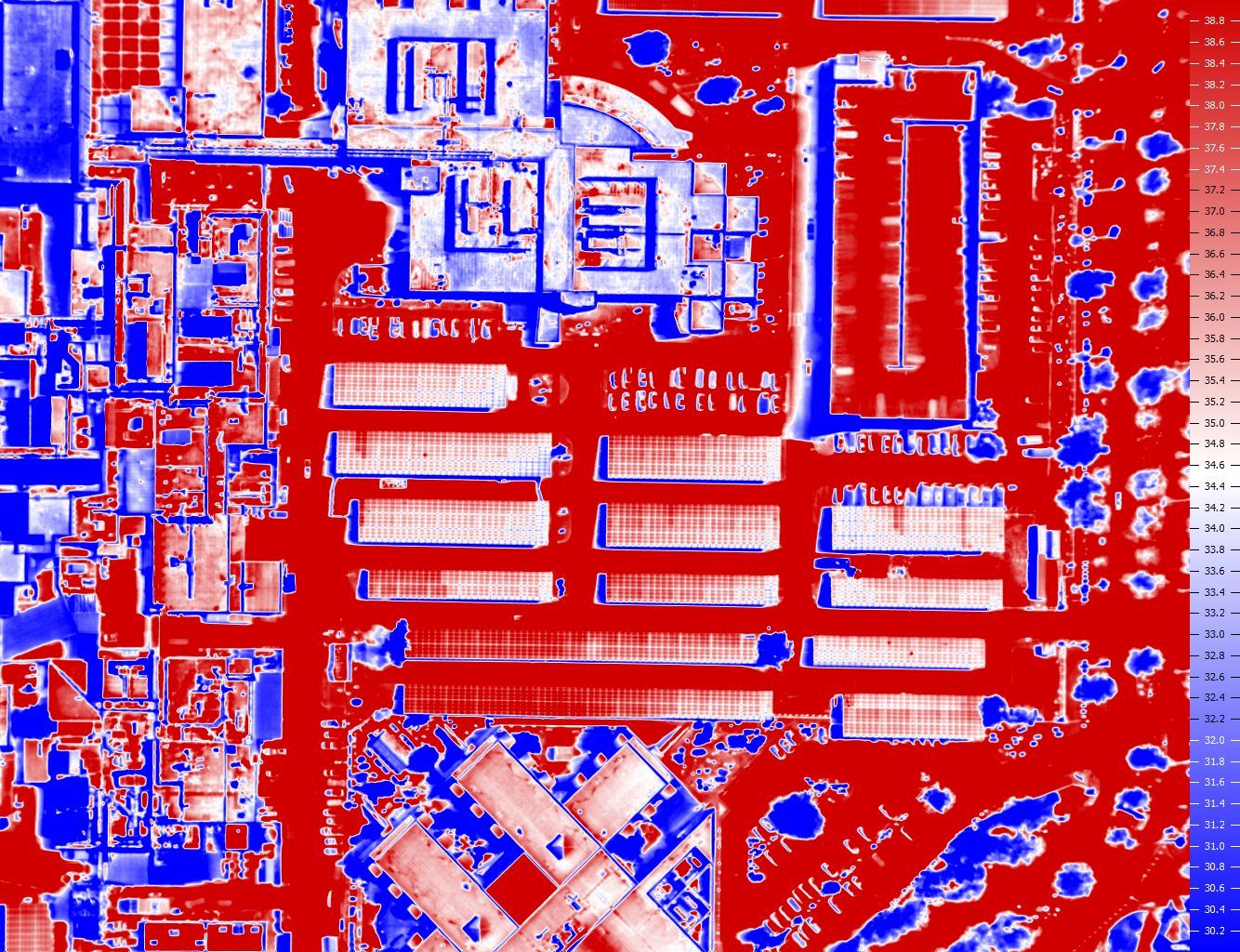

The right image is a great example. Thermal hot spots stand out clearly against cooler zones. Areas marked in blue represent colder regions, such as shaded areas beneath trees. In sharp contrast, the hotter zones — marked in red — include features like car parks.

The image on the left shows a square with solar panels. Working panels appear in paler shades, such as white or light red. Non working ones stand out, as they appear in dark red, which also indicate a thermal hotspots. The trees as well as green areas, by contrast, appear blue and are considerably cooler.

Choose the GSM 5000

The GSM 5000 has proven itself as a versatile, future-ready solution for demanding airborne projects. Whether integrating cutting-edge thermal sensors, expanding corridor mapping capacity, or simply upgrading from earlier mounts, the GSM 5000 offers unmatched performance and ease of use.

Download here the product datasheet – including a full comparison between the GSM 5000 and its predecessor, the GSM 4000.

Subscribe today!

Keep yourself informed about SOMAG and the latest Gyro Mount technology.

We will send you regular information about:

- exhibitions and event invitations

- new products, services and videos

- latest application examples, projects and partnerships