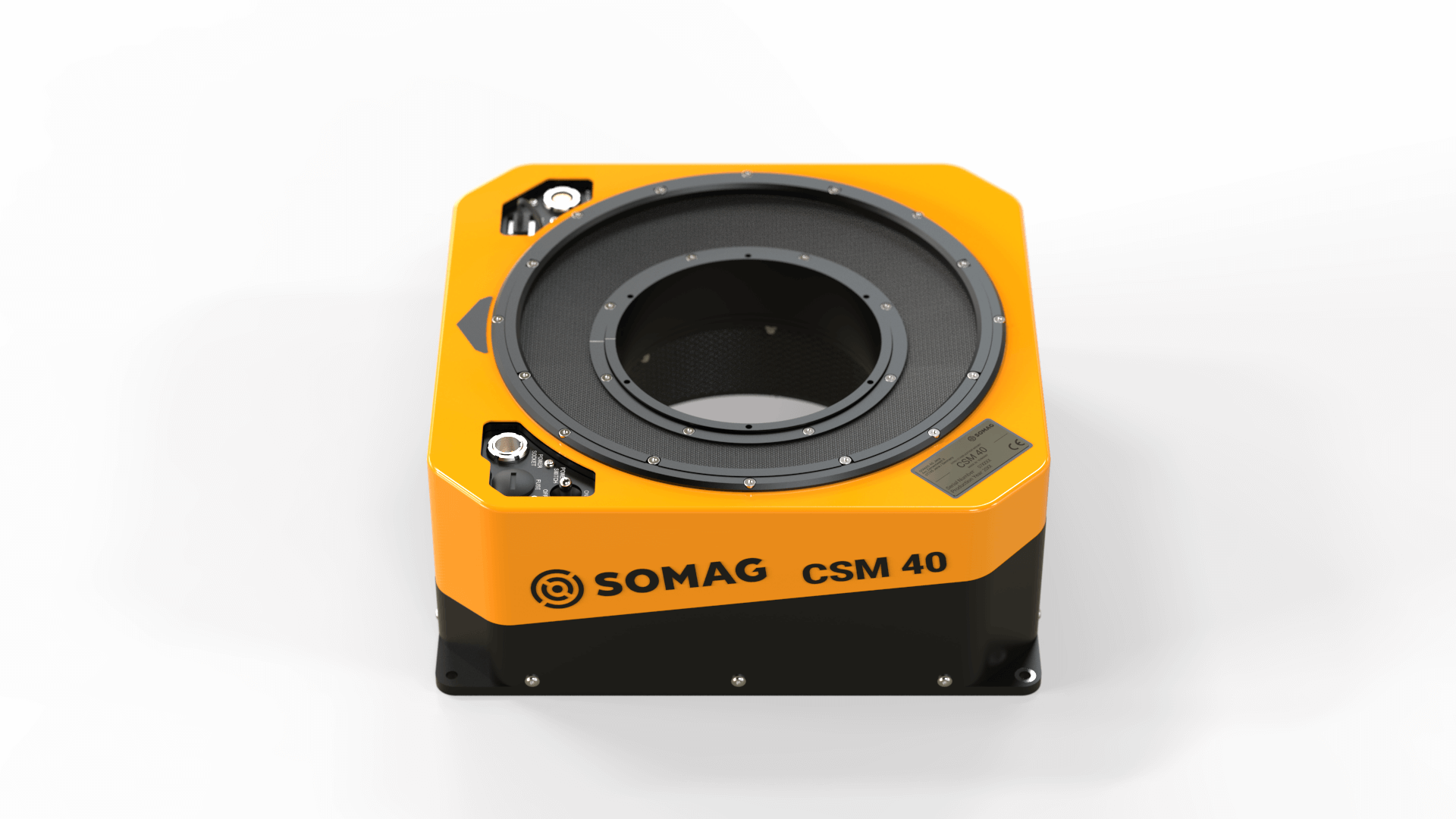

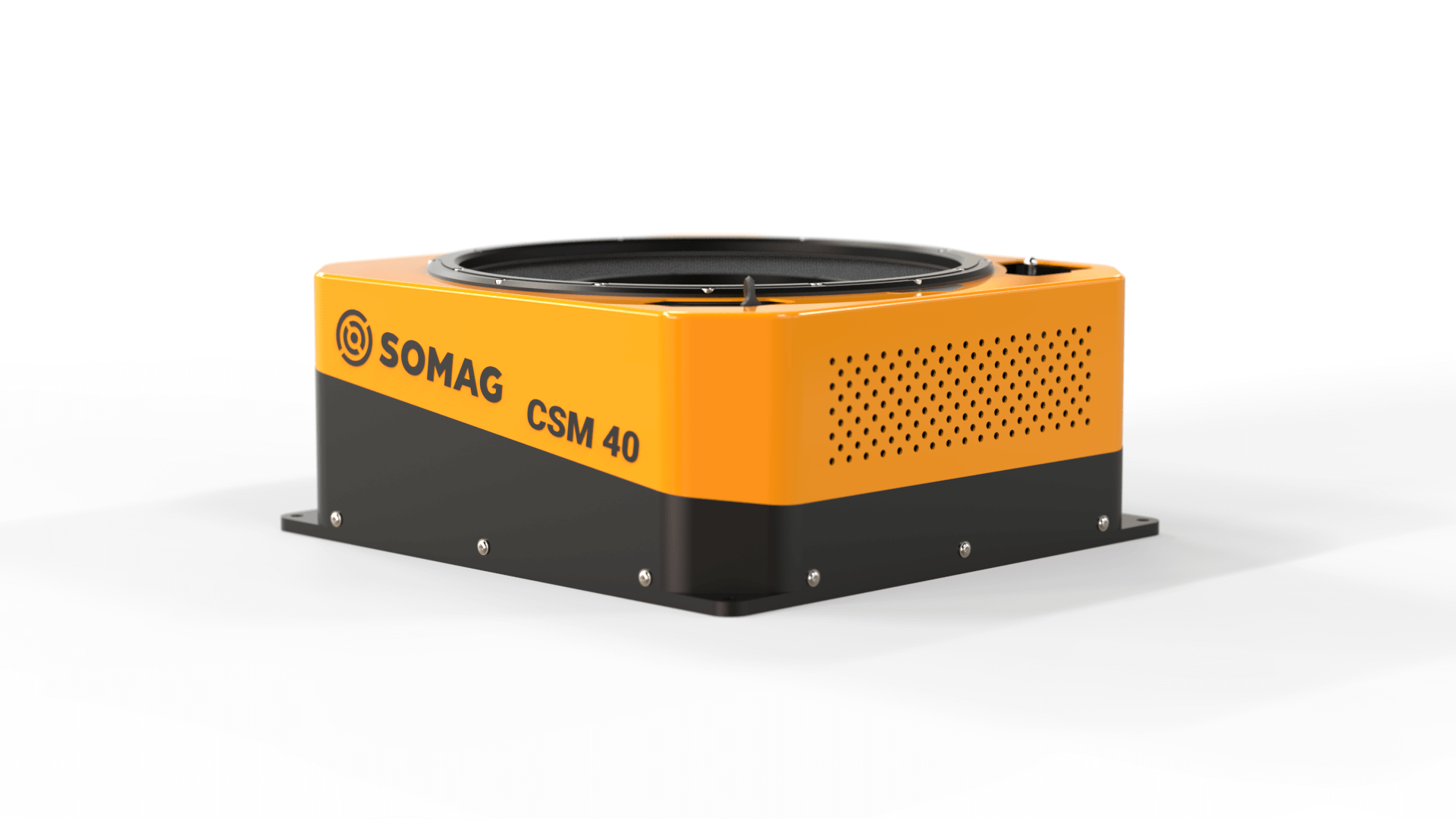

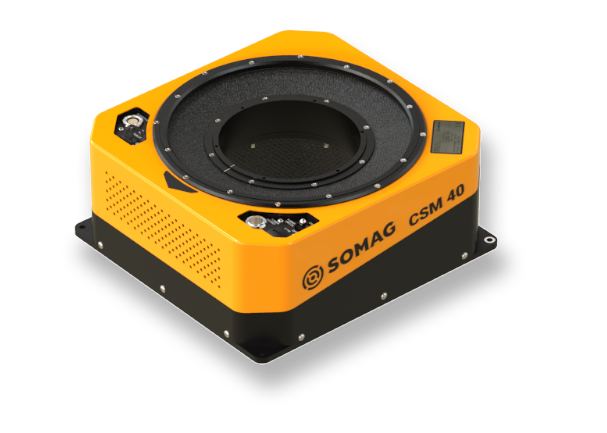

The Compact Stabilization Mount 40 is part of a new Mount generation that boasts compactness and cost-efficiency.

Advantages

- Compact and lightweight design for single medium format cameras and scanners

- Largest angular stabilisation range of airborne Gyro Stabilization Mount series

- Most cost-effective airborne Gyro Mount suitable for entry level users

Performance meets cost efficiency

The CSM 40 is the most cost-efficient stabilization platform of the SOMAG airborne mounts and at the same time offers the largest angular stabilization range of this product line. It is the optimal entry-level stabilization system for operators who have high expectations in terms of stabilization performance and long-term product reliability.

Small Mount – Big effect

The ultra-low weight and the small form factor enable the CSM 40 to be flexibly deployed even in UAVs and ultralight aircraft. The electromechanical gimbal system ensures highly accurate data capturing with single medium format sensors up to 15 kg by compensating for roll, pitch and yaw motions that may occur during flight due to turbulence and flight maneuvers. The CSM 130 successor was developed to achieve unmatched image accuracy in mapping and surveying projects. Try it out and see the difference!

Like all SOMAG airborne stabilization platforms, the CSM 40 can be fully operated by a Flight Management System. An input of external IMU data can add an additional performance boost. You also need an extra vibration isolation? Then SOMAG’s optional Passive Vibration Isolation Ring (PaVIR) is exactly what you are looking for.

Specifications

| Angular Stabilization Ranges | Pitch at 0° Roll: Roll at 0° Pitch: Yaw (Drift): | ≤± 15.0° ≤± 15.0° ≤± 25.0° |

| Residual Angular Rate1 | ≤± 0.5°/s rms | |

| Residual Deviation | without IMU support1: with IMU support1,2: | ≤ 0.3° rms ≤ 0.08° rms |

| Payload3 | 0…15 kg | 0…33.1 lbs | |

| Mass | 5.2 kg | 11.5 lbs | |

| Dimensions (Regular Leveling Positions) | Length: Width: Height3: | 290 mm | 11.4 in 275 mm | 10.8 in 121 mm | 4.8 in |

| Usable Diameter | Ø130 mm | Ø5.1 in | |

| Operating Temperature | -15 °C…+55 °C | -5 °F…+131 °F | |

| Storage Temperature | -55 °C…+85 °C | -40 °F…+185 °F | |

| Communication Interfaces | RS 232 | USB | |

| Operational Voltage | 28 VDC (24…30 VDC) | |

| Average Power Consumption at Operational Voltage | 15 W | |

| Peak Power Consumption at Operational Voltage | 60 W | |

| Applied Standards | RTCA DO-160-G, EUROCAE-14G, ISO 7137, 2006/42/EC Machinery |

| Preliminary data, subject to change 1 Vehicle angular motion <10°/s and with typical data acquisition profile frequency spectrum 2 Deviation from perpendicular depends on accuracy of used IMU 3 Payload installation level: 110 mm (4.3 in) | Minimum: 86 mm (3.4 in) | Maximum 134 mm (5.3 in) |

Applications

For precise airborne surveying and blur-free images taken from above, they have become indispensable and an established part of the overall equipment: Gyro Stabilization Mounts. Installed into the fuselage of aircrafts, they compensate for its roll, pitch and yaw movements to keep the sensor in a leveled position. Would you like to see how SOMAG customers benefit from their Mounts? We have compiled a series of application examples for you that show the diversity of application scenarios for our devices.

Downloads

Discover all Gyro Stabilization Mounts with their specifications at a glance in our new product catalog. Below you will also find Mount-specific documentation. Do you need other documents? Then do not hesitate to contact us. We will gladly send you manuals on request.

Mount Control App and Software Features

Mount Control App

For all Gyro Stabilization Mounts, SOMAG provides a self-developed Mount Control App with numerous features. It is your all-in-one tool for managing your Mount. The app is part of the standard scope of delivery of each device and is delivered on a USB stick together with the Mount.

Software Features

SOMAG offers optional Software Features which allow you to customize your Mount individually to your mission requirements. Feature management and settings can conveniently be made in the SOMAG Mount Control App. Get the most out of your stabilization platform and learn more about the optional Software Features.