Meet SOMAG at Intergeo 2025.

SOMAG AG Jena will be exhibiting at Intergeo 2025, taking place in Frankfurt, Germany, from October 7–9, 2025. Intergeo is the world’s leading event for geodesy, geoinformation, and land management, bringing together experts and industry leaders from across the globe.

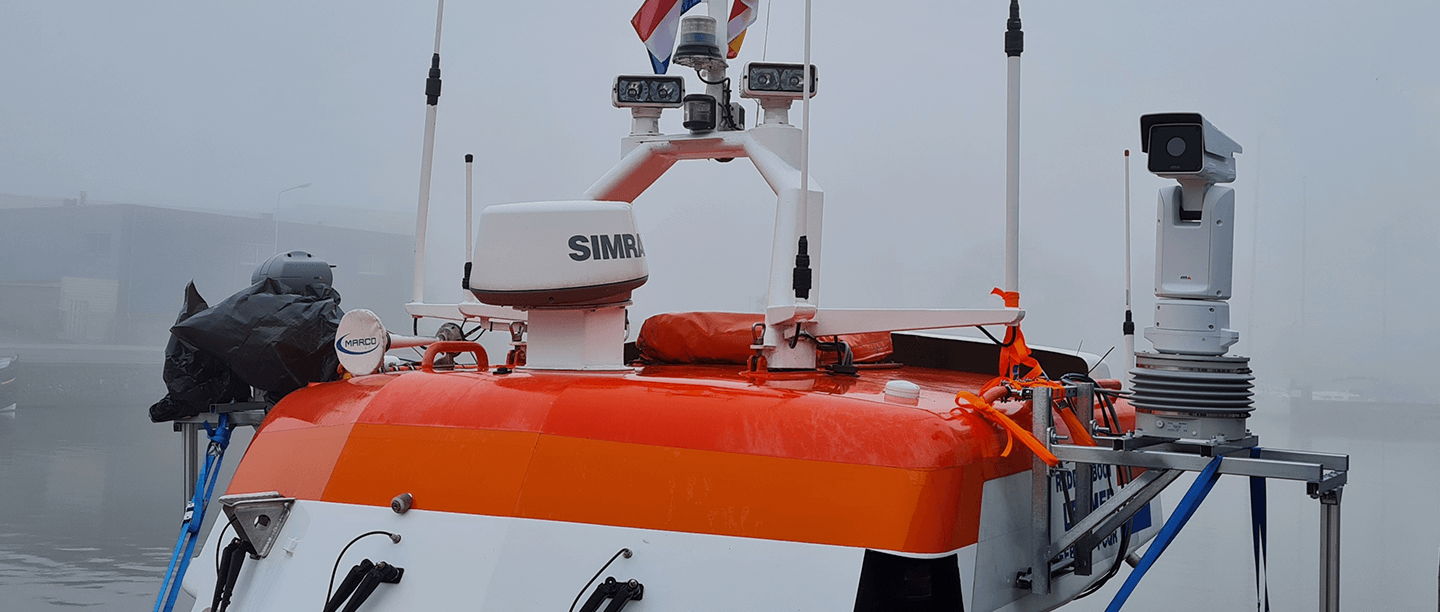

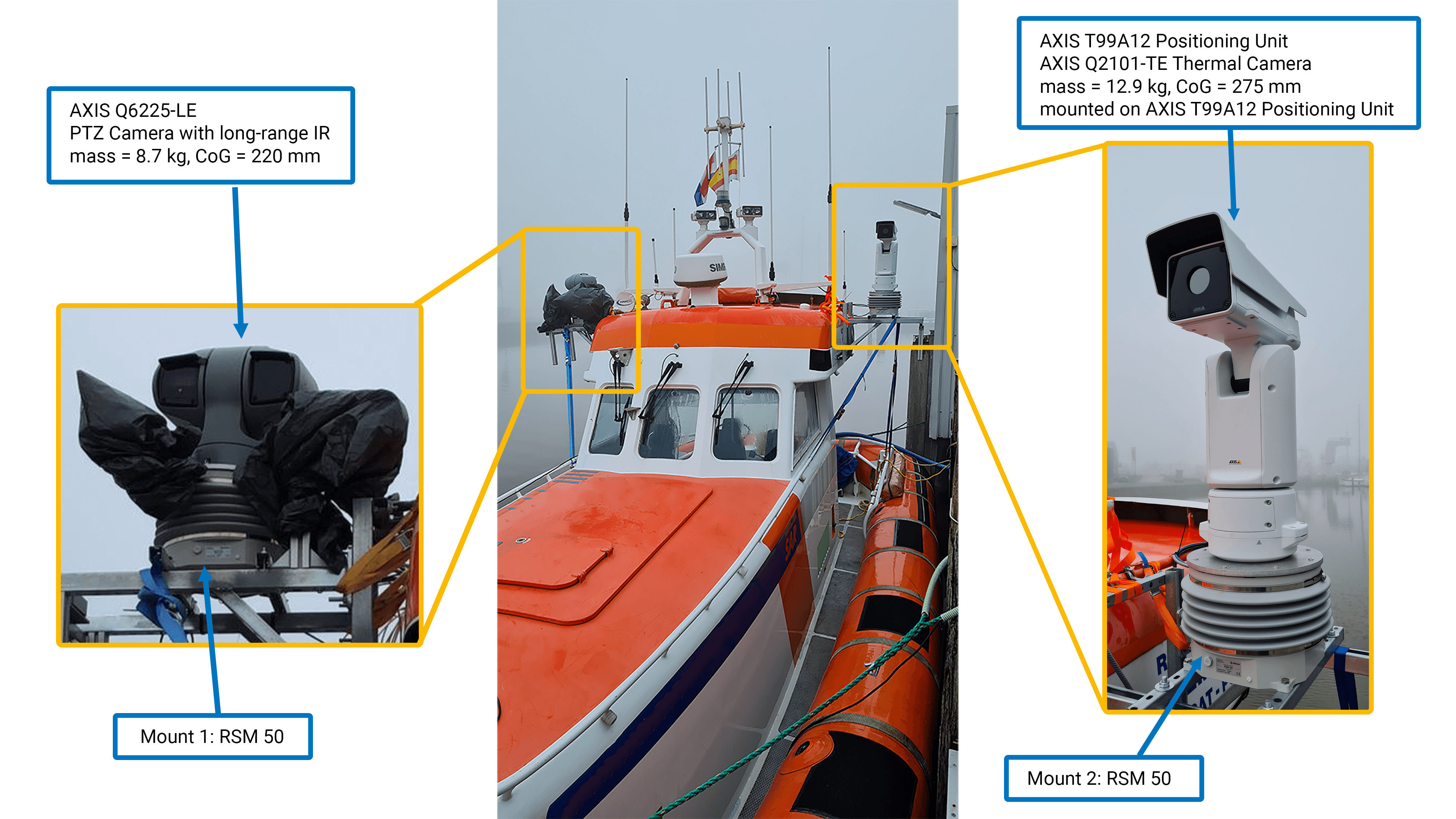

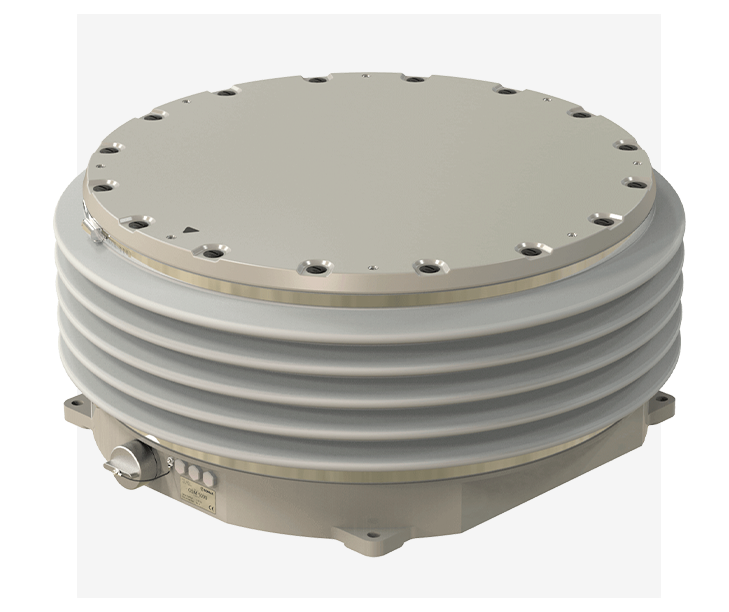

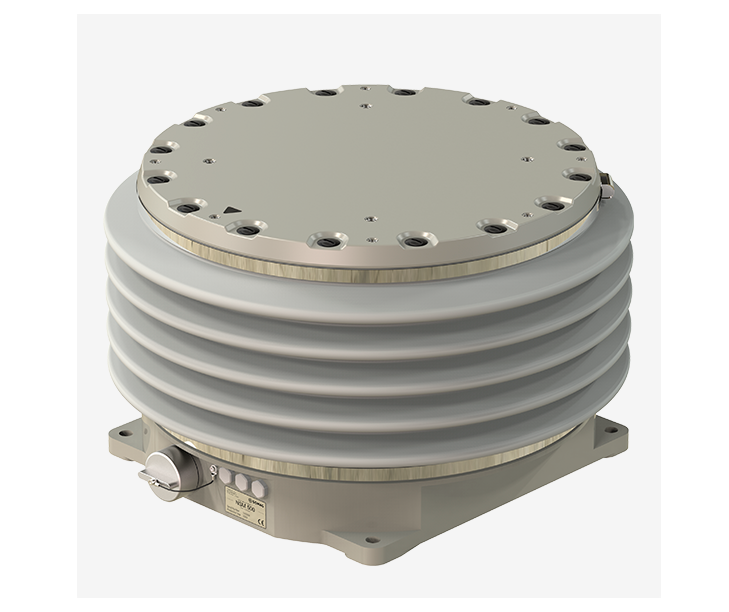

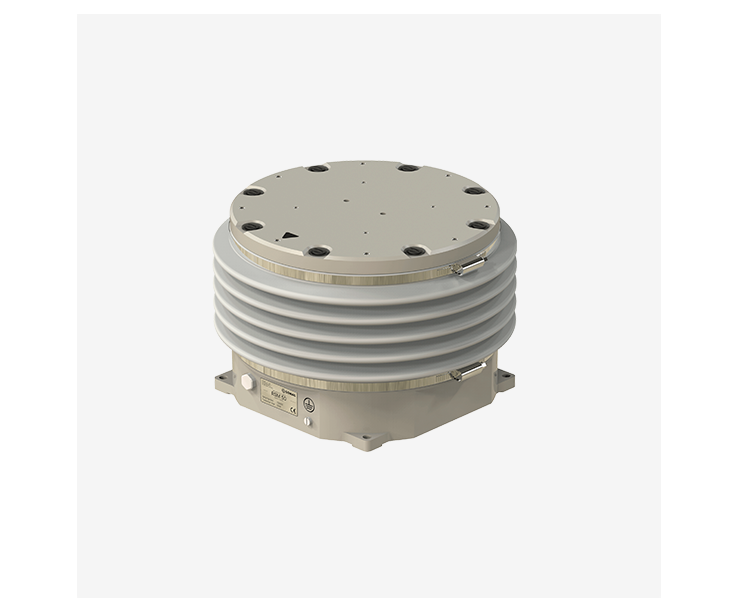

Visit us at our joint booth 0B.050 in Hall 12, where we will be co-exhibiting with TopoFlight Systems. At the SOMAG stand, you can explore our latest advancements in Gyro Stabilization Mounts for airborne, marine, and land-based applications.

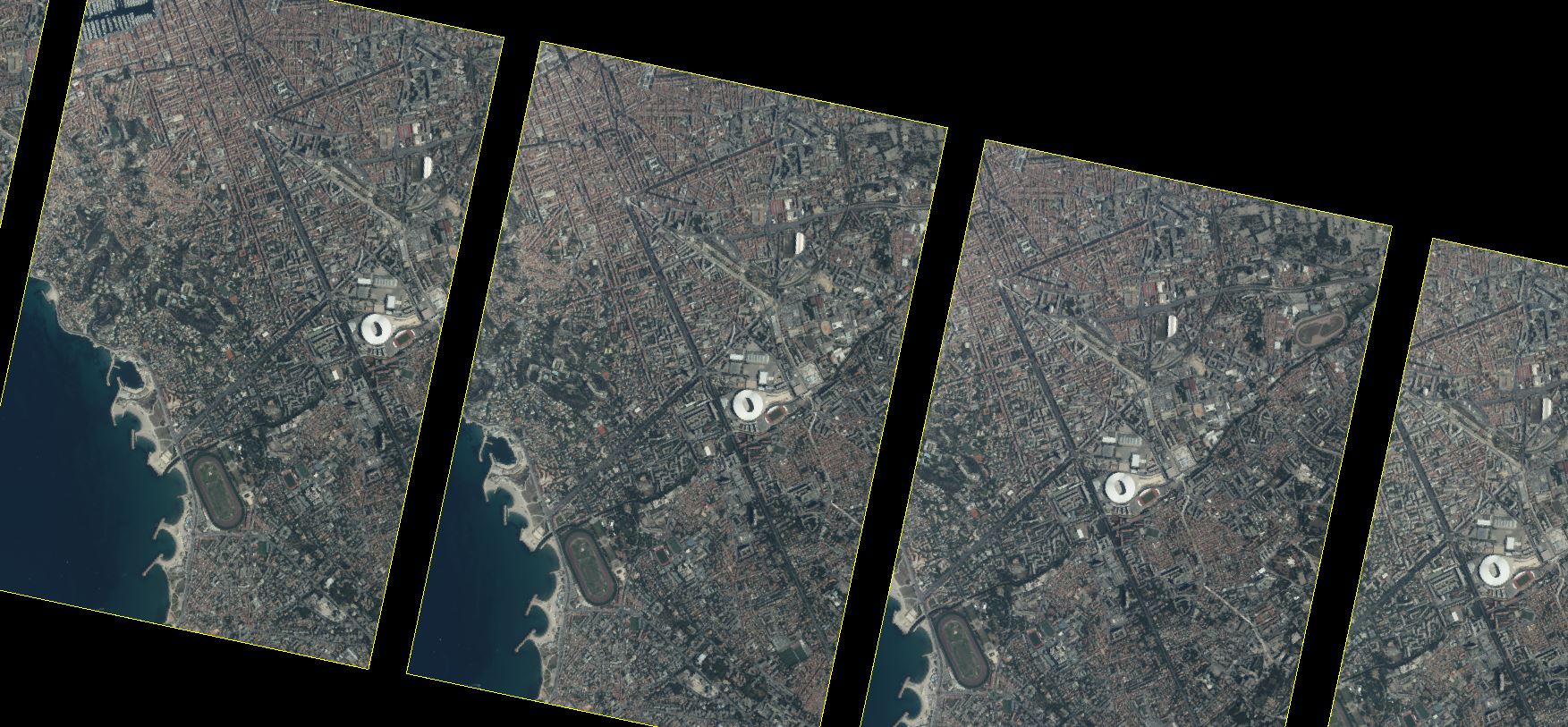

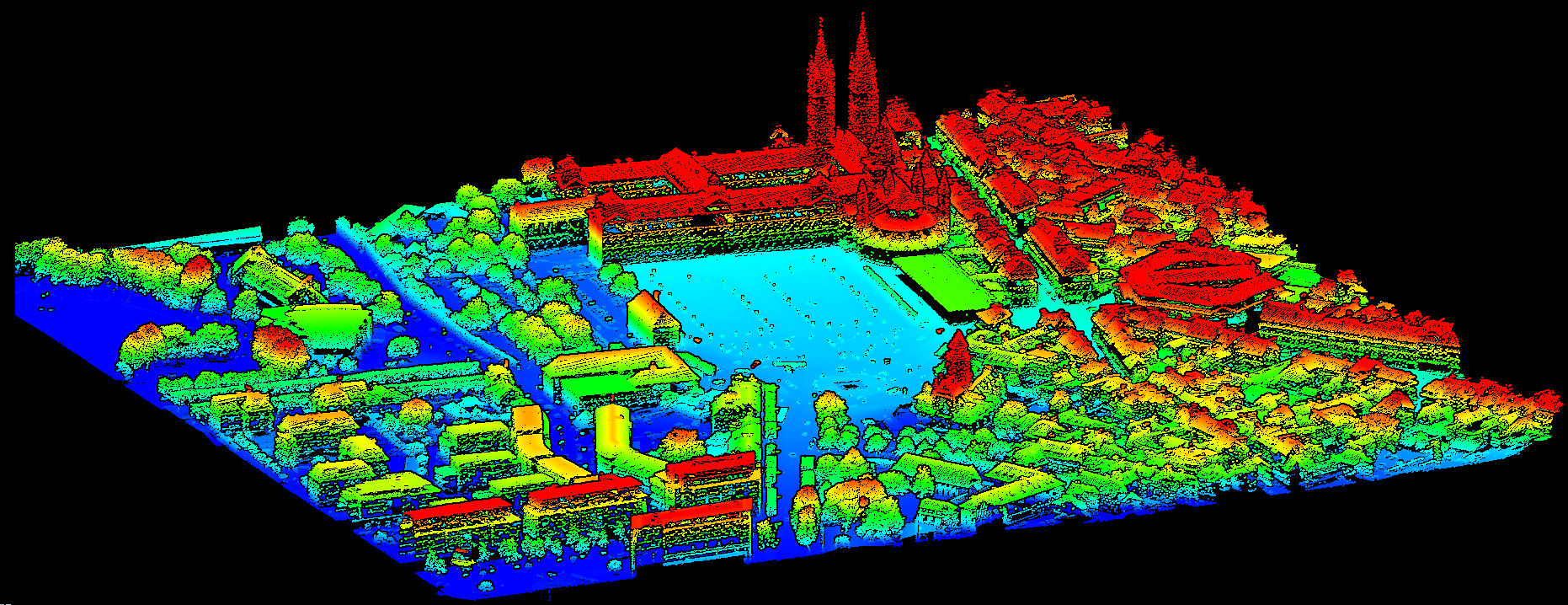

We will be presenting our brand-new GSM 5000 – a high-performance Gyro Stabilization Mount designed specifically for airborne data acquisition, offering cutting-edge technology for enhanced stability and sensor precision.

Visit our booth to explore how SOMAG’s advanced technology improves data quality and sensor performance in dynamic environments. Our team will be happy to advise you on the right solution for your mission.

Top 6 reasons to check out the GSM 5000

- Expanded motion range – enhanced performance

- No manual adjustments needed

- Enhanced field of view

- 100 % backward compatible to current GSM 4000 installations

- Future-proof communication interfaces (Ethernet & RS232-COMBI)

- Larger diameter for bigger sensor systems (Ø 425 mm)

Free tickets for our customers

We offer our customers free vouchers for visiting Intergeo on all three opening days. To get your ticket please contact us at and we’ll then send you your personal voucher code via e-mail.

Meet our experts

Andreas Steps

CEO

Phone: +49 3641 633 68 12

E-Mail: a.steps@somag-ag.de

Let’s connect on LinkedIn

Sebastian Schreiber

CTO

Phone: +49 3641 633 68 0

E-Mail: s.schreiber@somag-ag.de

Let’s connect on LinkedIn

Sören Lieske

Sales Manager

Phone: +49 3641 633 68 18

E-Mail: s.lieske@somag-ag.de

Let’s connect on LinkedIn

Lukas-Maximilian Graf

Operations Manager

Phone: +49 3641 633 68 25

E-Mail: l-m.graf@somag-ag.de

Let’s connect on LinkedIn