SOMAG Launches Passive Vibration Isolation Technology for Naval and Land-Based Sensor Systems

SOMAG AG Jena is proud to announce the expansion of its proven vibration isolation technology to land and maritime platforms. For the first time, our Passive Vibration Isolation Ring (PaVIR) is available for use with pan-tilt cameras, EO/IR systems, radar, and other mission-critical sensors operating on naval vessels and ground vehicles.

Whether installed on a high-speed patrol boat or a high-mobility military vehicle, vibration is a constant threat to sensitive surveillance and targeting systems. Engine rumble, wave shocks, and terrain impact can quickly lead to component wear, data degradation, or even system failure.

To counter this, SOMAG has adapted its field-proven isolation technology—originally designed for aerial applications—to meet the rugged requirements of naval and land operations. The result is a robust, passive mechanical solution that dramatically reduces vibration exposure and preserves the performance and integrity of your sensor systems in the harshest environments.

Why Vibration Isolation Matters for Naval and Land Platforms

Military and surveillance equipment in mobile environments face harsh mechanical stress:

Naval systems:

- Hull vibrations from diesel engines, water jets, or wave impacts

- Long-term fatigue from constant motion at sea

- Saltwater corrosion combined with physical shock loads

Land-based systems:

- Terrain-induced shock and vibration from wheeled or tracked vehicles

- High-amplitude jolts from off-road operation

- Vibration transfer from vehicle frames to sensor mounts

Without proper isolation, these forces can lead to:

- Misalignment of optics and pan-tilt mechanisms

- Cracked housings or mechanical fatigue

- Electronic failures such as microfractures in PCBs

- Motion blur, video instability, and targeting inaccuracy

What Is a Passive Vibration Isolation Ring (PaVIR)?

The PaVIR is a passive mechanical damping system engineered to reduce vibration before it reaches sensitive sensor equipment. It uses various materials and elements to interrupt the vibration path between the platform and the payload. This system is unique on its own because it has to be tailored to each individual solution, mounting system and stabilization mount.

Unlike active systems, the PaVIR requires no power, no software, and no calibration—it’s reliable and rugged. The frequency of maintenance intervals and the longevity of the system vary depending on the individual solution and application, but are low in general.

Ideal for:

- Stabilized pan-tilt camera systems,

- Electro-optical/infrared (EO/IR) sensors,

- Surveillance, reconnaissance, and targeting equipment,

- Distance measurements using stadiametric methods

Key Advantages of PaVIR for Naval and Land Use

Increases Equipment Lifespan: Reduce mechanical wear and vibration-induced failure over time.

Improves Video and Imaging Quality: Eliminate motion blur, jitter, and sensor instability during operation.

Easy to Integrate and Maintain: No wiring or power required—mechanical-only solution for quick integration into harsh environments.

Designed for Harsh Conditions: Rugged materials for maritime and land use, including corrosion resistance and shock durability.

Designed for the Field – Naval and Land

SOMAG’s PaVIR can be integrated in systems worldwide, including:

- Shipboard surveillance systems

- Vehicle-mounted perimeter observation units

- Fixed installations on coastal security platforms

- Mobile defense and homeland security systems

Each ring is tailored to your payload’s weight and specific setup to be easily adapted to existing stabilization platforms. That means no vibration ring is mass produced and for that it is always fitted for your personal needs and preferences.

Who Should Use PaVIR?

SOMAG’s PaVIR serves a wide range of users – to summarize just a few:

- Defense integrators working on naval ISR platforms

- Security forces using mobile ground surveillance units

- Coast Guard and maritime patrol operators

- Measurements with highly sensitive sensors such as gravimeters

- OEMs integrating stabilized sensors into ruggedized systems

- Distance measurement using ultrasound, laser, GPS, interferometry or other stadiametric methods

Integration Options

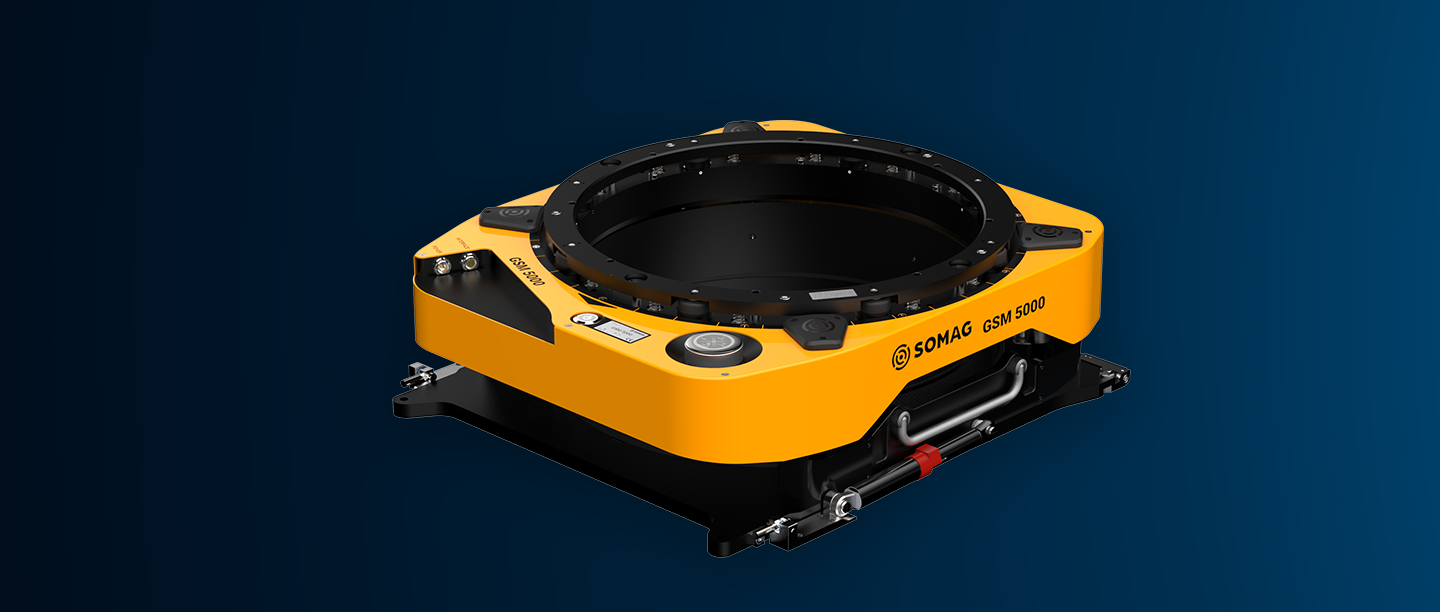

This type of vibration isolation solution is a proven standard in our airborne product line and comes as part of the standard equipment for systems such as SOMAG GSM 5000 and DSM 400.

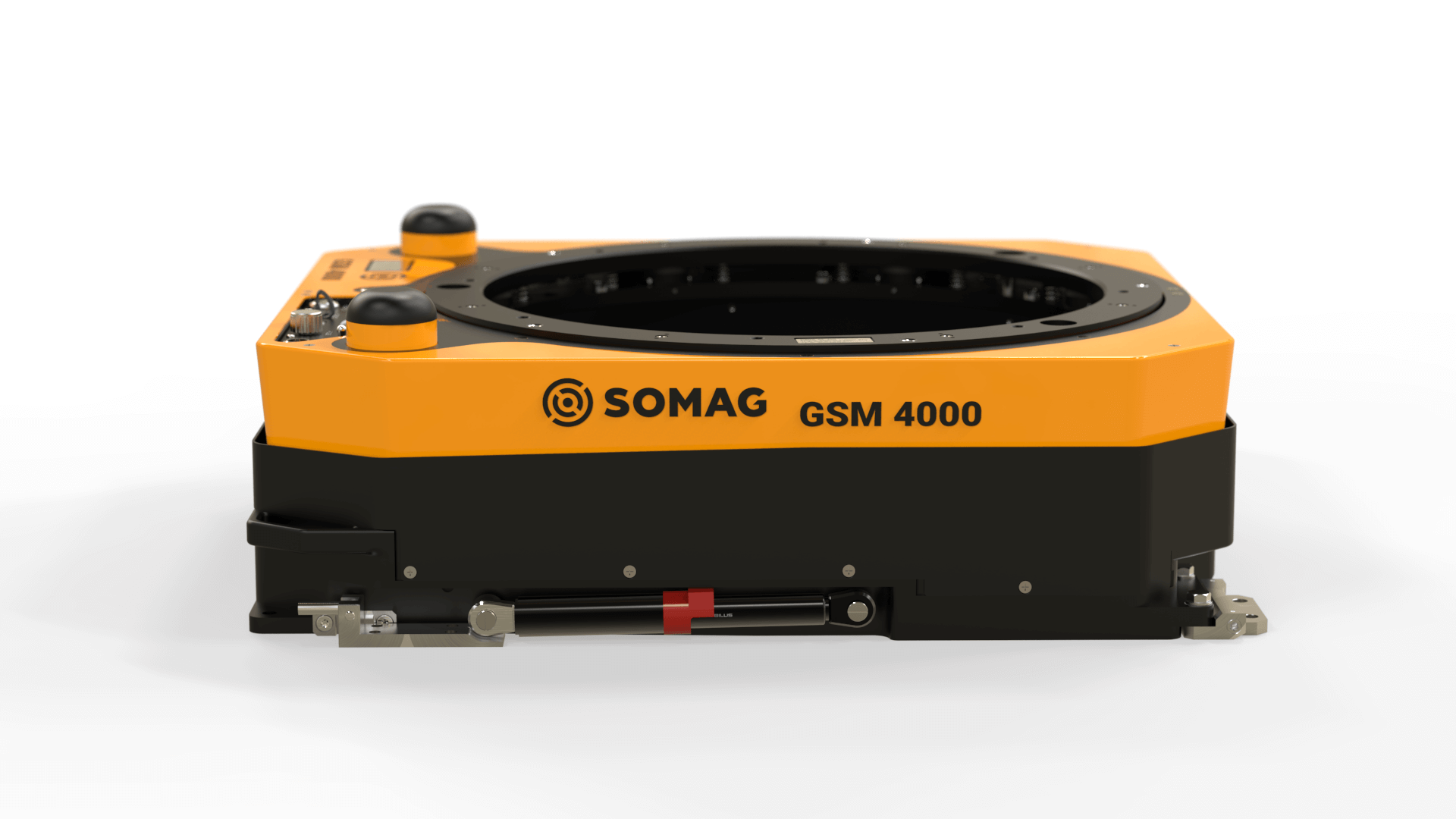

For our land gyro mounts and marine gyro stabilizers – including the RSM 50, NSM 500, and OSM 5000 – it is available as an optional accessory, providing enhanced performance and improved sensor protection in demanding operational environments.

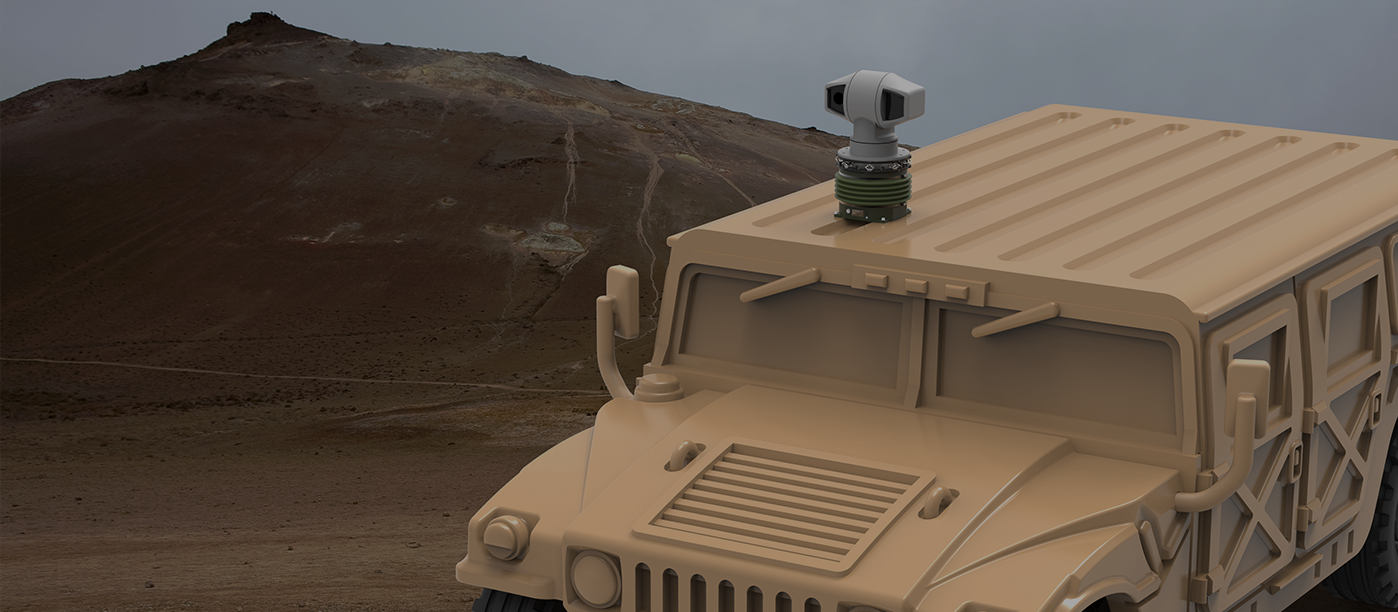

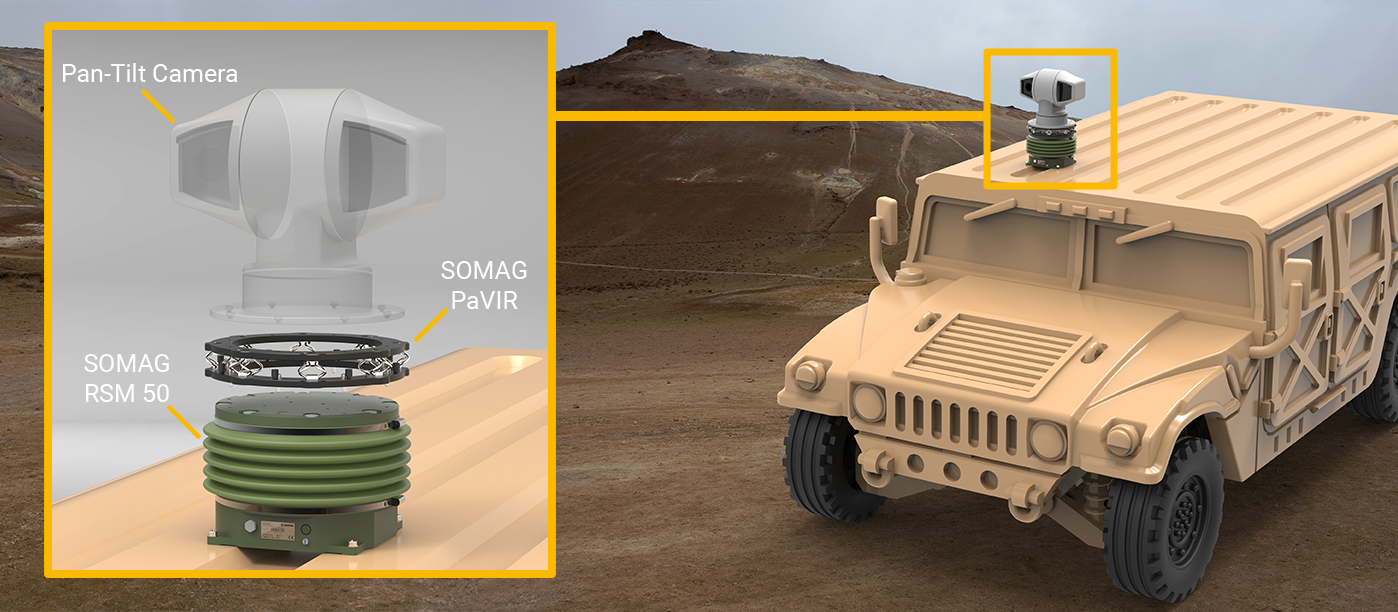

The image below shows a SOMAG RSM 50 mount equipped with a SOMAG PaVIR and a pan-tilt camera for surveillance on a high mobility multipurpose wheeled vehicle.

The isolation ring can be easily installed between the payload (in this case the pan-tilt camera) and the stabilization mount itself. Though the general configuration and installation varies from PaVIR to PaVIR regarding the final design for each application.

Visit Us at DSEI London 2025 / Booth S12-330

We’re showcasing our latest vibration isolation and stabilization technology at DSEI London 2025. You’ll find us at booth S12-330 in the Future Tech Hub. Come see the PaVIR in action, explore integration options, and speak with our experts. Ready to protect your sensors and your data?

Contact us today to request a custom solution or learn more about the PaVIR.

SOMAG Sales Team

Sören Lieske

Sales Manager

Phone: +49 3641 633 68 18

E-Mail: s.lieske@somag-ag.de

Let’s connect on LinkedIn

Jana Franck

Sales Coordinator

Phone: +49 3641 633 68 15

E-Mail: j.franck@somag-ag.de

Let’s connect on LinkedIn

Subscribe today!

Keep yourself informed about SOMAG and the latest Gyro Mount technology.

We will send you regular information about:

- exhibitions and event invitations

- new products, services and videos

- latest application examples, projects and partnerships